Compressor Winding Testing at Ace Hotel Palm Springs

Compressor Winding Testing at Ace Hotel Palm Springs

At American Cool, Heat, Air & Commercial Refrigeration, we believe that accurate diagnostics are just as important as the repair itself. On a recent service call to the Ace Hotel in Palm Springs, our technicians performed an essential test on a compressor suspected of failure—checking the windings for continuity and resistance.

These tests are a key part of identifying whether a compressor is in good shape, has internal electrical issues, or is completely grounded. Here’s how we approached this job and what it revealed about the system’s condition.

The Problem: Compressor Not Starting

The hotel’s staff reported that the HVAC system was not cooling properly in a section of the building. Based on early symptoms—including no compressor operation and no refrigerant movement—we suspected an electrical issue within the compressor itself.

Instead of replacing components blindly, we followed our process of detailed diagnostics to determine whether the compressor windings were still in working order or if the compressor had failed electrically.

Step 1: Testing Compressor Windings for Continuity

The compressor windings are internal coils that generate the magnetic field needed to operate the motor. If these windings are broken, shorted, or grounded, the compressor won’t start—and trying to power it up in that state can damage other system components.

Our first test involved using a multimeter to check continuity between the three terminals on the compressor:

♦ Common (C)

♦ Start (S)

♦ Run (R)

We tested continuity between:

♦ C to S

♦ C to R

♦ S to R

All three should show continuity (a closed circuit) if the windings are intact. In this case, the readings were within expected values, which indicated the windings were not open or broken.

Step 2: Measuring Resistance (Ohms) Between Windings

Next, we used our multimeter to measure the resistance in ohms between the same terminals. This test gives us a picture of how healthy the windings are and whether they match the manufacturer’s specifications.

A normal compressor will show:

♦ The highest resistance between Start and Run (S-R)

♦ Mid-range between Start and Common (S-C)

♦ Lowest between Run and Common (R-C)

We verified the readings and confirmed that the windings were not shorted or burned, and resistance levels were balanced, suggesting no internal faults.

Step 3: Checking for a Grounded Compressor

The final and most critical test was to check if any of the terminals were shorted to ground. A grounded compressor occurs when internal winding insulation breaks down and connects to the compressor housing—creating a direct electrical path to ground. This is a serious failure and can trip breakers or damage other electrical parts.

To test for grounding, we measured resistance between each terminal and the compressor shell (metal body).

✔️ The readings showed infinite resistance (OL), meaning no continuity to ground—exactly what we want to see.

This confirmed the compressor was not grounded and still electrically intact.

Conclusion: Compressor Still in Good Condition

After completing all tests, we determined that the compressor windings were not damaged, resistance was within spec, and the unit was not grounded. With this information, we were able to rule out compressor failure and shift our focus to external electrical components and control issues.

This job highlights the importance of proper diagnostics in HVAC repair. Swapping out a compressor without confirming the real issue would have resulted in wasted time, unnecessary costs, and extended downtime—something no hotel wants during peak season.

Why Diagnostics Matter in Commercial HVAC

At properties like Ace Hotel Palm Springs, where comfort and guest experience are key, preventative testing and accurate troubleshooting are critical. Testing components like compressor windings saves money and prevents deeper system failures by catching issues before they escalate.

Whether it’s checking continuity, resistance, or grounding, American Cool, Heat, Air & Commercial Refrigeration has the expertise to get the job done right the first time.

Need a Pro to Check Your HVAC System?

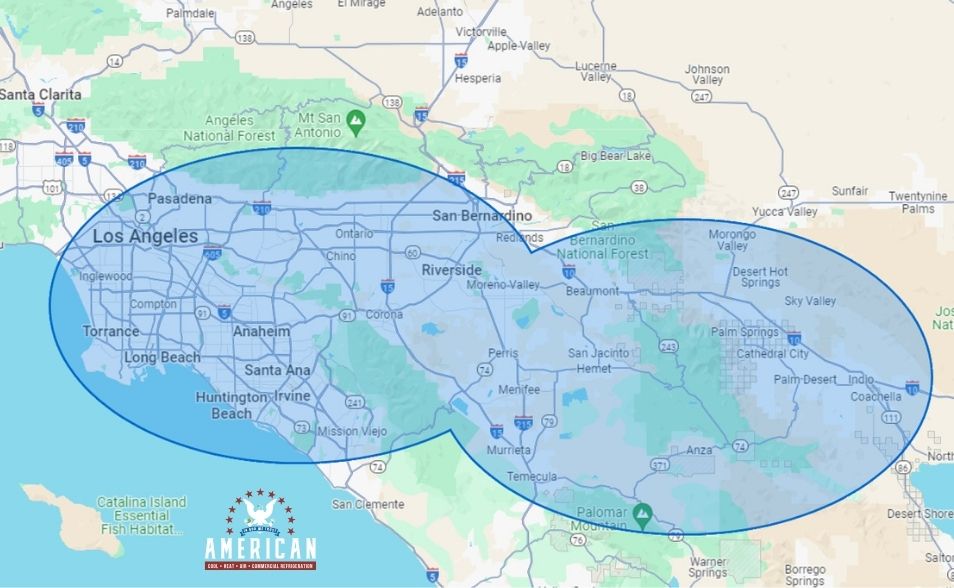

EXTENSIVE SERVICE COVERAGE FOR COMMERCIAL HVAC & REFRIGERATION SOLUTIONS

No Commercial HVAC or Refrigeration job is too small or too far for us. While our primary branches are located in Palm Desert and Rancho Cucamonga, California, we’re dedicated to reaching customers wherever they are in need.

Proudly serving cities across California, including Indio, La Quinta, Indian Wells, Bermuda Dunes, Thousand Palms, Cathedral City, Rancho Mirage, Santa Ana, Fontana, Moreno Valley, Glendale, Ontario, Garden Grove, Palm Desert, Irvine, Anaheim, Riverside, Palm Springs, and extending to Los Angeles and beyond. Your satisfaction is our priority, no matter the distance or scale of the project.

AMERICAN COOL HEAT AIR BRANCHES

PALM DESERT, CA

77564 Country Club Dr. #142,

Palm Desert, CA, 92211

RANCHO CUCAMONGA, CA

10601 Civic center Dr 100H,

Rancho Cucamonga 91730