How a Pump Down Refrigeration System Works: Understanding the Basics

How a Pump Down Refrigeration System Works: Understanding the Basics

In the world of refrigeration, automatic pump down systems play a critical role in protecting the longevity of compressors, ensuring efficient operation, and maintaining system integrity. While these systems may seem complex, their purpose and operation can be broken down into straightforward components that are vital for anyone working in refrigeration, especially those transitioning from air conditioning.

What is a Pump Down Refrigeration System?

A pump down refrigeration system is designed to automatically pump refrigerant from the low side of the system into the condenser and liquid line receiver when there is no active call for refrigeration. This occurs during periods of defrost or when the temperature in the refrigeration box meets its desired set point.

The key objective of this process is to protect the compressor from refrigerant migration during the off cycle, which can occur in both warm and cold climates. Without a pump down system, refrigerant could condense and mix with oil in the compressor crankcase, causing damage over time, including loss of lubrication, overheating, and mechanical wear. This can lead to compressor failure, which is costly and time-consuming to repair.

Components of a Pump Down System

A typical automatic pump down system is made up of three main control components, each of which works together to manage the pump down cycle:

-

Thermostat:

The thermostat is mounted near the evaporator in the refrigeration box and reads the air temperature as it returns from the evaporator coil. When the temperature inside the box rises above the set point, the thermostat sends power to the liquid line solenoid.

-

Liquid Line Solenoid:

The liquid line solenoid, commonly referred to as the pump down solenoid, is a normally closed solenoid valve. When refrigeration is needed, the solenoid opens, allowing refrigerant to flow. It closes during the off cycle, initiating the pump down process by stopping refrigerant flow into the evaporator.

-

Low-Pressure Controller:

his controller monitors the suction pressure on the low side of the system. It ensures the compressor remains off until the system pressure rises above a pre-set threshold. Once the pressure reaches this point, the controller energizes the contactor coil, starting the compressor and condenser fan motors.

The Pump Down Process

When the system calls for refrigeration, the thermostat triggers the liquid line solenoid, allowing refrigerant to flow through the system. This increase in pressure on the low side causes the low-pressure controller to close, starting the compressor and fan motors.

Refrigerant travels through the system, cooling the refrigerated space. As the system reaches the desired temperature, the thermostat deactivates, closing the liquid line solenoid and stopping the refrigerant flow. The compressor continues to run, pulling refrigerant into the condenser until the suction pressure drops to the cutout setting. Once this pressure is reached, the compressor and fans turn off, completing the pump down.

Why Pump Down Systems Are Crucial

Compressor protection is the primary reason for implementing an automatic pump down system. Without it, refrigerant migration during the off cycle can lead to flooded starts, where refrigerant condenses in the crankcase and mixes with oil, resulting in oil foaming and damage to the compressor.

By evacuating refrigerant from the low side, the pump down system ensures the compressor starts up under safe conditions, preventing catastrophic failure and prolonging the life of the equipment.

Key Takeaways

-

Pump down refrigeration systems protect compressors from damage during off cycles by moving refrigerant to the condenser and liquid line receiver.

-

The system consists of a thermostat, liquid line solenoid, and low-pressure controller, which work in tandem to manage the refrigerant cycle.

-

Flooded starts, caused by refrigerant migration, can severely damage compressors, making pump down systems essential for reliable operation.

For refrigeration technicians and those new to the field, understanding the working principles of pump down systems is critical to ensuring the longevity and efficiency of refrigeration units. Whether dealing with walk-in coolers or other applications, knowing how these components interact can help prevent costly compressor failures.

Need Professional Refrigeration Services?

At American Cool Heat Air, we specialize in the installation, repair, and maintenance of refrigeration systems, including those using pump down technology. Whether you need help with commercial refrigeration or looking to improve system efficiency, our experienced technicians are here to assist. Contact us today for a consultation and keep your refrigeration systems running smoothly and efficiently.

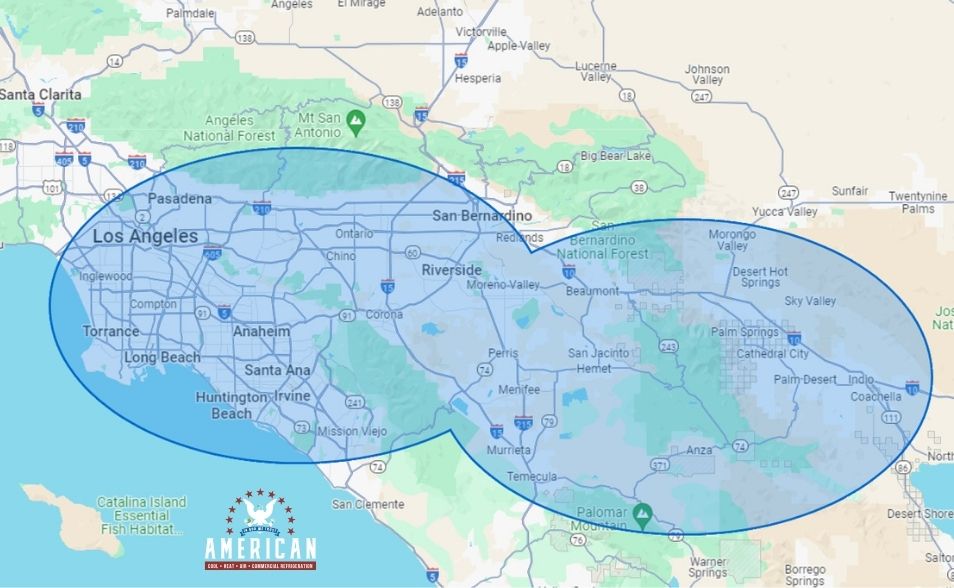

EXTENSIVE SERVICE COVERAGE FOR COMMERCIAL HVAC & REFRIGERATION SOLUTIONS

No Commercial HVAC or Commercial Refrigeration job is too small or too far for us. While our primary branches are located in Palm Desert and Rancho Cucamonga, California, we’re dedicated to reaching customers wherever they are in need.

Proudly serving cities across California, including Indio, La Quinta, Indian Wells, Bermuda Dunes, Thousand Palms, Cathedral City, Rancho Mirage, Palm Desert, Palm Springs, and extending to Los Angeles and beyond. Your satisfaction is our priority, no matter the distance or scale of the project.

AMERICAN COOL HEAT AIR BRANCHES

PALM DESERT, CA

77564 Country Club Dr. #142,

Palm Desert, CA, 92211

RANCHO CUCAMONGA, CA

10601 Civic center Dr 100H,

Rancho Cucamonga 91730