HVAC Repair in Palm Desert: Troubleshooting a Rooftop Unit Step-by-Step

HVAC Repair in Palm Desert: Troubleshooting a Rooftop Unit Step-by-Step

Commercial HVAC problems can strike anywhere, and in the desert climate of Palm Desert, maintaining cooling efficiency is especially critical. In this blog, we’ll share a recent experience where we diagnosed and repaired a rooftop HVAC unit on an Intellipak system for a client in Palm Desert. The issue involved a failed condensing fan motor, and we’ll guide you through the troubleshooting process, necessary repairs, and some best practices for HVAC maintenance in hot climates.

Identifying the Problem: Suspected Fan Motor Failure in Palm Desert

In the scorching heat of Palm Desert, reliable HVAC performance is essential. Our client reported a suspected issue with one of the condensing fan motors on a rooftop unit. After arriving on site, our team inspected the Intellipak system, which had six condensing fan motors controlled by four contactors, and began troubleshooting.

Step 1: Checking Electrical Components

Before diving into the testing mode, it was essential to ensure that the electrical components were functioning correctly:

-

Inspecting Fuses:

The first step was to check all the fuses for the motors to confirm none were blown. This ensures that power could flow correctly to the motors.

-

Testing for Grounding Issues:

Additionally, testing for any electrical short to the ground was necessary to rule out potential grounding issues that could damage components.

Once the electrical checks were completed, the fuses were confirmed to be in good condition, and there were no grounding problems.

Step 2: Running the Unit in Test Mode

Next, it was time to enter the system’s service mode and force the condensing fan motors to run:

-

Service Mode Configuration:

The unit was set to activate all condensing fan outputs, including variable-speed motors, to identify the malfunctioning motor.

-

Manual Testing:

y manually turning on the fan motors, it became apparent that circuit 2B was the one experiencing issues. While the other motors ran smoothly, the motor associated with this circuit did not respond.

Step 3: Isolating the Faulty Motor

The investigation revealed that the motor for circuit 2B was not functioning despite having voltage present on the contactor, which indicated a likely mechanical or internal electrical failure in the motor itself. As this HVAC system used three-phase motors without run capacitors, the problem was narrowed down to the motor or the contactor.

Step 4: Ordering Replacement Parts

After confirming the faulty motor, the necessary replacement parts were ordered:

-

New Motor and Contactor:

Both the condensing fan motor and contactor were ordered to ensure the repair could be carried out promptly and efficiently.

Replacing the Faulty Components

Once the replacement parts arrived, the next phase was to swap out the faulty components:

-

Verifying the Correct Motor:

Before beginning the replacement, the new motor was inspected to confirm it matched the original specifications, such as RPM, voltage (460V), and amp draw (1.8A).

-

Removing the Old Motor:

Care was taken to note the positioning of the fan blade on the motor shaft, ensuring proper installation of the new motor.

-

Installing the New Motor and Contactor:

The new motor was installed with the fan blade aligned as per the original setup. Additionally, the new contactor was wired in, and the electrical connections were checked for accuracy.

Step 5: Testing the New Setup

After installing the new components, the system was powered back on to test the repairs:

-

Checking Motor Direction and Functionality:

The fan motor was tested to ensure it rotated in the correct direction, delivering proper airflow across the coil.

-

Measuring Amp Draw:

Each phase’s amp draw was measured to confirm the motor operated within the specified limits, ensuring it would not overheat or draw excessive current.

Best Practices: Preventive Measures

To avoid future failures, a few preventive steps were taken:

-

Covering the Motor Shaft:

Foil tape was used to seal off the top of the motor shaft, preventing water from accumulating and causing rust.

-

Regular Maintenance Checks:

Scheduled maintenance should include periodic inspection of motor amp draws, checking for wear on electrical components, and ensuring all fuses and connections remain in good condition.

Conclusion

Troubleshooting and repairing an HVAC rooftop unit may seem daunting, but by following a systematic approach, it becomes a manageable task. In this case, diagnosing the issue involved checking electrical components, running the unit in test mode, and isolating the faulty motor. With proper installation of the replacement motor and contactor, the system was restored to full functionality. Regular maintenance and preventive measures will help ensure the longevity and efficiency of the HVAC system.

Don’t Let HVAC Problems Slow You Down – Contact Us Today!

Experiencing HVAC issues can be a hassle, especially in the intense heat of Palm Desert. If you’re facing cooling problems or need expert maintenance, our team is here to help. We specialize in keeping commercial HVAC systems running smoothly and efficiently.

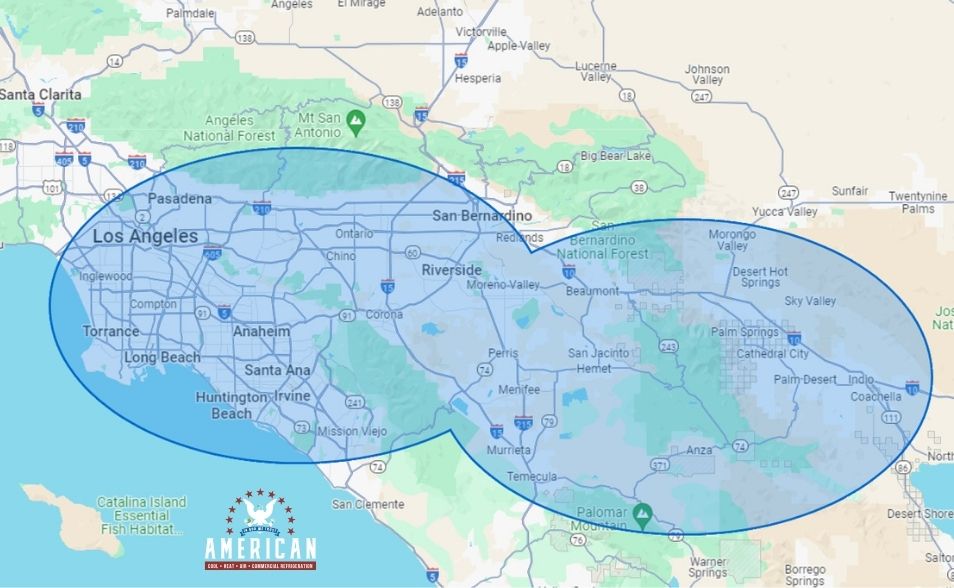

EXTENSIVE SERVICE COVERAGE FOR COMMERCIAL HVAC & REFRIGERATION SOLUTIONS

No Commercial HVAC or Refrigeration job is too small or too far for us. While our primary branches are located in Palm Desert and Rancho Cucamonga, California, we’re dedicated to reaching customers wherever they are in need.

Proudly serving cities across California, including Indio, La Quinta, Indian Wells, Bermuda Dunes, Thousand Palms, Cathedral City, Rancho Mirage, Santa Ana, Fontana, Moreno Valley, Glendale, Ontario, Garden Grove, Palm Desert, Irvine, Anaheim, Riverside, Palm Springs, and extending to Los Angeles and beyond. Your satisfaction is our priority, no matter the distance or scale of the project.

AMERICAN COOL HEAT AIR BRANCHES

PALM DESERT, CA

77564 Country Club Dr. #142,

Palm Desert, CA, 92211

RANCHO CUCAMONGA, CA

10601 Civic center Dr 100H,

Rancho Cucamonga 91730